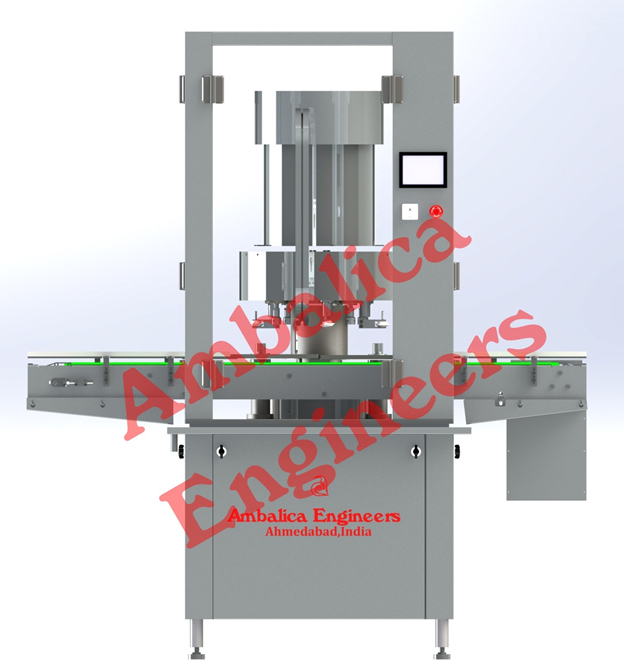

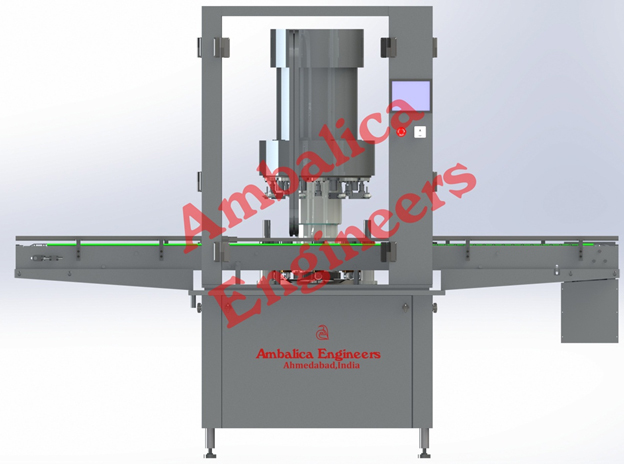

Duly Stoppered vials are fed on the conveyor enter into the infeed star wheel which transfers it to center star wheel under sealing head. Aluminium caps kept in vibratory bowl automatically orient caps in right direction before entering the delivery chute. The Vial during its rotation movement in the infeed star wheel picks up aluminum seal from the retaining finger of delivery chute and correctly position for sealing enters into center star wheel under sealing head where free spinning sealing rollers moves gradually inside to complete the sealing operation during rotational movement of sealing head and sealed vials are then transferred to outfeed stawheel and move on conveyor belt for next operation.

Technical Specifications:

| Machine Model | AVCS-80 | |

| No. of Heads | Four | |

| Output/Minute | 40-100 Vials | |

| Working direction | Left to Right | |

| Electric Characteristic | Main motor | 1.5 HP/230V/1440 RPM/Single Phase/50 Hz |

| Conveyor Motor | 0.50HP/230V/1440 RPM/Single Phase/50 Hz | |

| Power Supply | Single Phase/3 Phase, 4 Wire | |

| Input Specifications | Vial dia. | 16mm to 52mm |

| Vial height | 25mm to 110mm | |

| Cap dia. | 13mm & 20mm | |

| Overall dimensions | 1600mm L x 921mm W x 1825mm H | |

| Net Weight | 500 kgs. | |

| Gross Weight | 750 kgs. | |

(The above specifications may change with the inclusion of latest technologies)