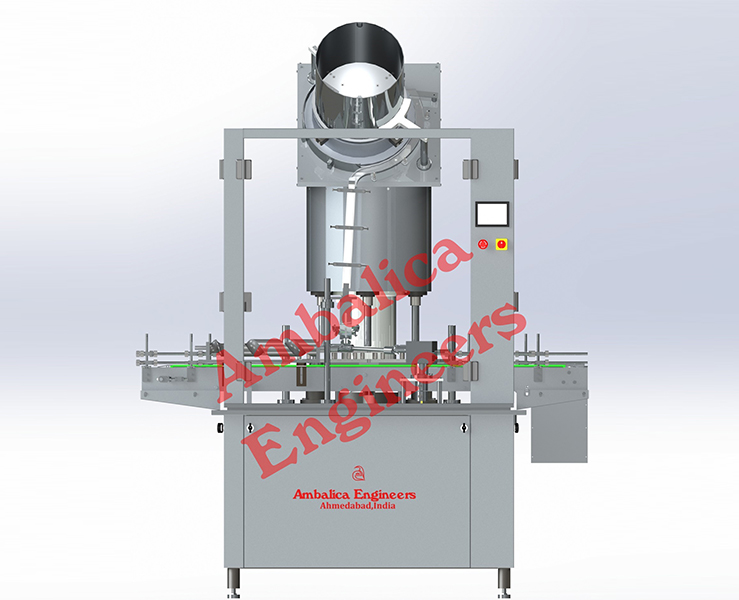

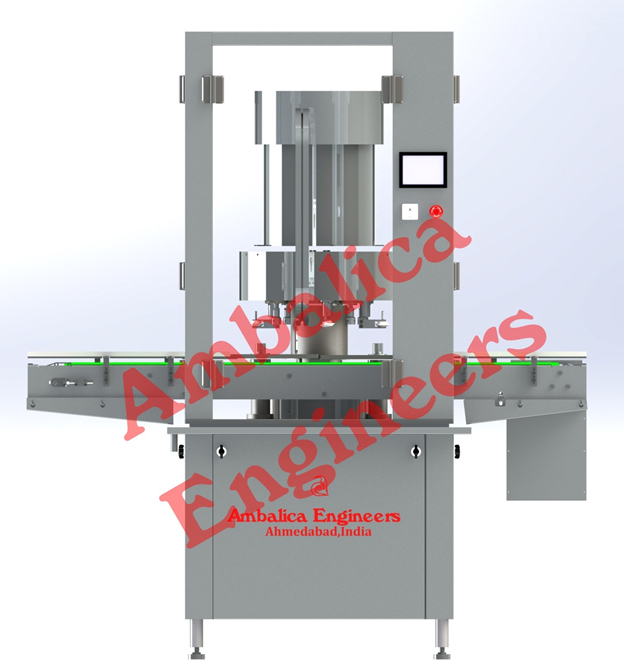

On-line filled containers are fed and guided on the moving SS/Plastic slat conveyor belt at the required speed enter in to infeed feed worm which transfers the bottle into infeed starwheel. The filled bottle moving in star wheel pick up cap from the cap chute and move under the Cap Pressing Head for perfect Cap Pressing on filled bottle. Then after the bottles moves on conveyor via outfeed starwheel for next operation.

Technical Specifications:

| Machine Model | ABPC-60 | ||

| No. of Heads | One | ||

| Output/Minute | 25- 50 bottles | ||

| Working direction | Left to Right | ||

| Electric Characteristic | Main motor | 2 HP/230V/1440 RPM/Single Phase/50 Hz | |

| Power Supply | Single Phase/3 Phase, 4 Wire | ||

| Input Specifications | Bottle dia. | 22mm to 70mm | |

| Bottle height | 50mm to 200mm | ||

| Cap dia. | 22mm, 25mm, 28mm and 32mm cap | ||

| Overall dimensions | 1600mm L x 856mm W x 1950mm H | ||

| Net Weight | 580 kgs | ||

| Gross Weight | 800 kgs. | ||

(The above specifications may change with the inclusion of latest technologies)